One of the most popular pieces of cultivation equipment on New Zealand farms is a roller.

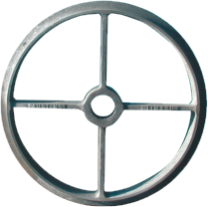

Most of our rollers will be either Cambridge or vee‑ring.

Many Cambridge and vee‑ring rollers have seed boxes fitted for sowing grass seed or brassica crops. Often farmers do not appreciate that there is a difference between Cambridge and veering rollers and the situation in which each is most effectively applied.

The vee‑ring roller was developed by Massey University in the 1950s specifically for small seed establishment in the dry pumice soils of the central plateau.

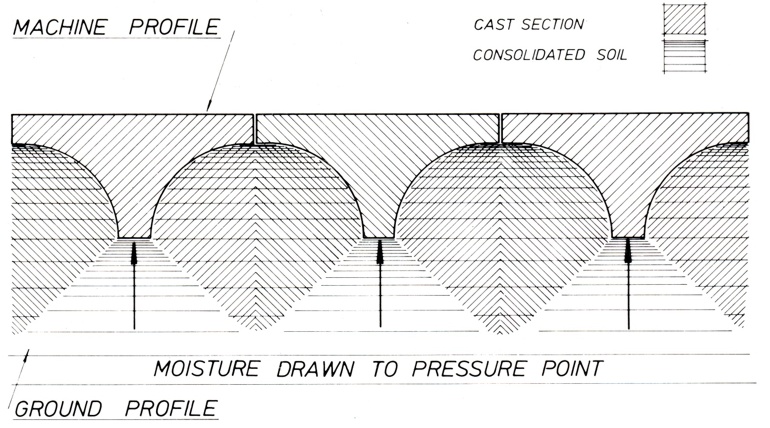

Since then it has been extensively used for pasture establishment in many soil types. When seed is broadcast behind the vee‑ring roller all seeds fall to the base of the vee grooves which are at 75mm (3in.) centres.

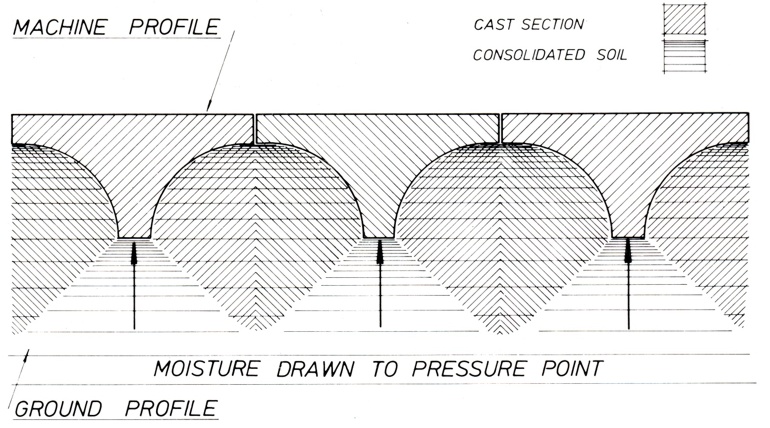

Moisture moves by capillary action to the base of the groove and, when harrowed to cover the seed, an ideal seedbed is created with the seed placed 15‑20mm deep.The Cambridge roller on the other hand is a cultivation tool, designed to consolidate the seedbed and crush clods.

Its shape is more pointed in order to concentrate weight to achieve this. The Cambridge roller is therefore not as well suited to seed sowing, as some seeds will fall on the soil surface between the grooves.

In summary, the Cambridge roller does an excellent job in consolidating the seedbed and crushing clods during cultivation and after sowing crops and pasture.

The vee‑ring roller conversely does an excellent job of seed sowing (for small seeds) and a reasonable job of consolidation during cultivation.

If a seedbox is fitted it should always broadcast seed behind the roller otherwise uneven seeding depth will result. Fitting the seedbox in front of the roller is an absolute "no no".

| WORKING WIDTH |

|

| (13ft) 4.00m Standard Rings |

2050 Kilos |

| (13ft) 4.00m Heavy Rings |

2400 Kilos |

| (13ft) 4.00m Extra Heavy Rings |

2880 Kilos |

|

|

| (12ft) 3.65m Standard Rings |

1950 Kilos |

| (12ft) 3.65m Heavy Rings |

2300 Kilos |

| (12ft) 3.65m Extra Heavy Rings |

2650 Kilos |

|

|

| (11ft) 3.35 Standard Rings |

1840 Kilos |

| (11ft) 3.35m Heavy Rings |

2140 Kilos |

| (11ft) 3.35m Extra Heavy Rings |

2450 Kilos |

|

|

| (10ft) 3.05m Standard Rings |

1680 Kilos |

| (10ft) 3.05m Heavy |

1950 Kilos |

| (10ft) 3.05m Extra Heavy |

2240 Kilos |

|

|

| (9ft) 2.80m Standard Rings |

1530 Kilos |

| (9ft) 2.80m Heavy Rings |

1790 Kilos |

| (9ft) 2.80m Extra Heavy Rings |

2050 Kilos |

|

|

| (9ft) 2.8m Roller Drill |

1800 Kilo |

| (10ft) 3.05m Roller Drill |

2000 Kilo |

| (11ft) 3.35m Roller Drill |

2200 Kilo |

| (12ft) 3.65m Roller Drill |

2400 Kilo |

|

|

| Transport Wheels |

|

| Hydraulic Transport Wheels |

|

|

Click on thumbnails to view - click arrows to scroll |

|

|

|

| |

Cambridge Roller: Use, Application and Effect

For Soil Conditioning, Moisture Conservation and Consolidation, Ground Levelling for better Crop and Pasture Production.

- Direct use over Mouldboard, Chisel, and Disc ploughed ground to break down and level surface for the next operation, Tyne and Disc cultivating, etc.

- For breaking down hard cloddy ground conditions.

- When used in conjunction with Harrows pulled between Tractor and Roller with extension drawbar the Harrows level out tractor wheel marks and leave a firm surface with moisture held in the ground for subsequent sowing.

- Multi Rear Hitch on Roller enables pullling of additional Harrows, Disc cultivators, etc. behind Roller. (3 & 4) Multi pulling of Implements gives considerable saving of fuel, man‑hours and Tractor usage.

- For moisture conservation and consolidation the results can be varied by speed of operation. Slow speed gives greater consolidation, faster speed reduces consolidation.

- In dry conditions moisture is drawn to compacted surface to give newly sown seed a better chance of earlier germination.

- Good consolidation also reduces ground shrinkage and open surface cracking in dry periods and prevents moisture evaporation.

- Cambridge Rollers are also used with grass sowing boxes mounted on the rear of the roller and driven off the roller axle, followed by attached light Harrows. This gives an ideal seed bed for pasture development especially in new pasture development from bush clearance as the shape of contact and weight tend to break up small twigs and branches left after clearing and cultivation.

- Rollers are also used after sowing of Wheat Oats and Pasture even after reasonable growth to conserve moisture and leave surface in better condition for subsequent harvesting and mowing, etc.

- Cambridge Rollers have a surface finish that leaves ground with better retention of moisture from rain. (Plain Surface Rollers have little water holding capacity). Detail sketch of surface finish below.

- Soil Types. Cambridge Rollers are used on all types of soil in New Zealand ranging from sand dune country in the North Auckland area, red volcanic soils and pumice areas in central North Island, river silt and loam soils in both Islands, also in the higher rainfall heavy soiled areas of Southland and the West Coast of the South Island. Used with reasonable care Rollers can be useful on stoney soils resulting in better surface condition for harvesting and mowing.

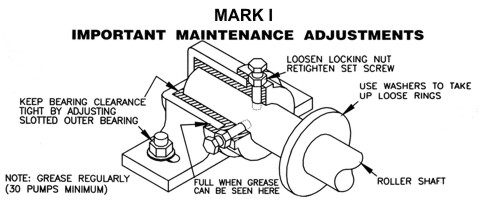

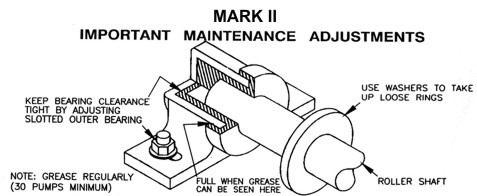

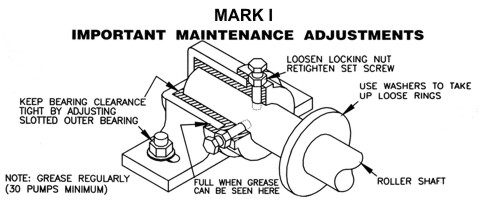

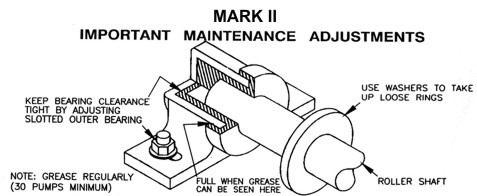

- Rollers are produced in all sizes up to 4 metres (13 ft) wide in various weights and diameter of the roller ring sections to suit individual needs. If wider rolling widths are required two or three units can be arranged to roll up to 10.5 metres (35 ft) in one operation. Roller frames are fabricated of rolled hollow section steel, all welded construction. Overseas rollers have bolted‑on drawbars and stays for shipping. All cast rings can turn independently on the axle and there is no skuffing of the surface while turning. Maintenance is minimal. Bearings require greasing every 2 hours of operation. Extra washers to take up wear are fitted when required, perhaps once every season with normal use.

The only expense would be occasional replacement of ring sections if subjected to undue conditions and perhaps bearing replacement if required through lack of greasing maintenance. Rollers in most New Zealand conditions would last the average Farmer a lifetime and even through the transition from horses to tractors the rollers have never become obsolete. Tractor power made possible the development of heavier modified rollers with improved efficiency and diversity of use.

We have stood by all of our products to date and we will continue to do so in all reasonable circumstances.

Components

Click HERE to download our roller specifications sheet!

| Overall Dia |

Axle Sizes |

|

Weight Per Ring |

510mm (20”) x |

2”, 2 ¼”, 65mm |

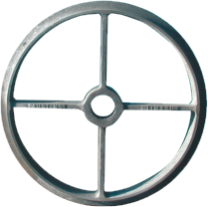

Standard Rings |

18 Kilos |

560mm (22”) x |

2”, 2 ¼”, 65mm |

Standard Rings |

20 Kilos |

610mm (24”) x |

2 ¼”, 65mm |

Standard Rings |

27 Kilos |

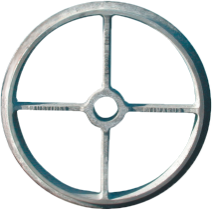

650mm (26”) x |

2¼”, 65mm, 75mm |

Standard Rings |

34 Kilos |

650mm (26”) x |

70mm or 75mm |

Heavy |

41 Kilos |

650mm (26”) x |

70mm or 75mm |

Extra Heavy |

47 Kilos |

650mm (26”) x |

65mm, 75mm |

V Type Rings for Seeder Roller Hollow |

31 Kilos |

650mm (26”) x |

65mm, 70mm, 75mm |

Ruapuna (Spares Only) |

38 Kilos |

635mm (25”) x |

65mm, 70mm, 75mm |

Extra Heavy 6 Spoke Rings (spares only) |

47 Kilos |

760mm (30”) x |

65mm, 70mm, 75mm |

5 Spoke Rings (spares only) |

47 Kilos |

650mm (26”) x |

65mm, 70mm, 75mm |

Furrow Press Ring |

47 Kilos |

| |

Roller Bearing drilled with studs (Standard Dustproof). 2” - 2¼” - 60mm - 2½

Roller Bearing as above with sprockets drilled with studs. 2” - 2¼” - 60mm - 2½

Roller Bearing large dust proof type drilled with studs 70mm, 75mm

Roller Bearing as above with sprockets drilled with studs 70mm, 75mm

Washers Plain 10mm, 12mm, 16mm x 57mm, 65mm, 70mm, 75m |

| |

|

|

|

| Standard |

Heavy |

Extra Heavy |

|

|

|

|

|

Copyright © - Austins Foundry Ltd

131 King Street Timaru New Zealand | FREEPHONE 0800 838 963 | Phone +64 3 688 8963 | Fax +64 3 688 3942 |